Aluminum honeycomb panels have rapidly gained prominence as a preferred choice in the construction and decoration industries. These innovative panels offer an exceptional blend of lightweight performance, durability, and aesthetic flexibility, making them ideal for a wide array of applications, from architectural facades to interior design elements. In this comprehensive article, we explore the advantages and disadvantages of aluminum honeycomb panels in depth, helping you make informed decisions for your next project.

Understanding Aluminum Honeycomb Panels

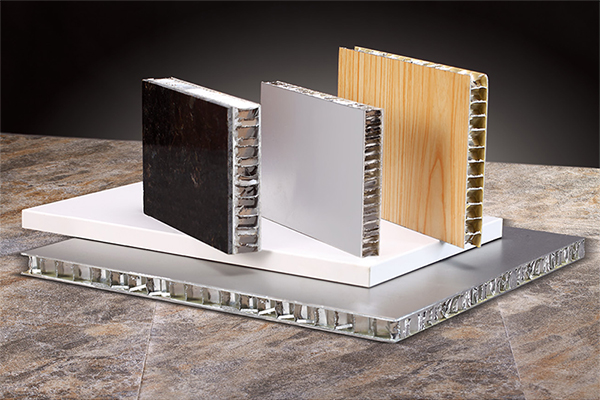

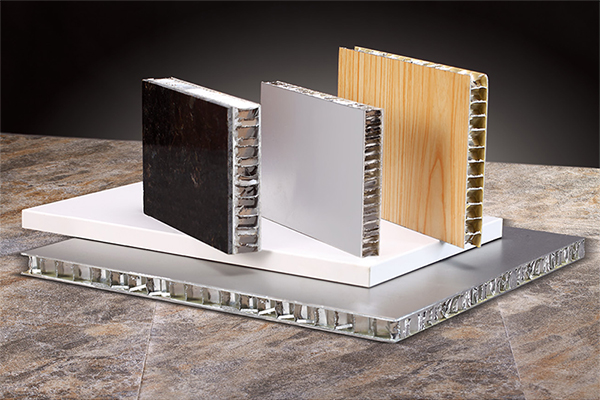

Aluminum honeycomb panels consist of two aluminum sheets bonded to an internal honeycomb core, typically made of aluminum as well. This structure is inspired by the natural hexagonal design of honeycombs, offering an impressive strength-to-weight ratio. The manufacturing process involves precision engineering and advanced bonding techniques to ensure that the panels deliver maximum rigidity while remaining incredibly lightweight. These panels are versatile, suitable for both exterior and interior applications, and offer superior performance in demanding environments.

Advantages of Aluminum Honeycomb Panels

1. Exceptional Strength-to-Weight Ratio

One of the most remarkable features of aluminum honeycomb panels is their outstanding strength relative to their weight. The honeycomb core provides excellent mechanical properties while minimizing weight. This makes installation easier and reduces structural load, especially in high-rise buildings or large-scale projects. Despite being lightweight, these panels can withstand substantial stress and pressure, ensuring long-term durability and stability.

2. Superior Flatness and Smooth Surface Finish

The continuous roller coating process applied to the surface aluminum sheets ensures perfect flatness and a uniform, scratch-resistant finish. Unlike traditional cladding materials, aluminum honeycomb panels resist warping and deformation over time, maintaining their aesthetic appeal. Additionally, the surface treatments such as fluorocarbon (PVDF) coatings provide exceptional resistance to UV radiation, chemicals, and corrosion, preserving the panel’s appearance for decades.

3. Outstanding Corrosion Resistance

Aluminum is naturally resistant to corrosion, but when combined with advanced surface treatments like fluorocarbon spraying, the panels become highly resistant to harsh weather conditions, salt spray, and industrial pollutants. This feature makes aluminum honeycomb panels an ideal choice for coastal buildings, urban facades, and industrial environments where long-term exposure to corrosive elements is a concern.

4. Diverse Aesthetic Options

Aluminum honeycomb panels offer a rich variety of colors and textures, including metallic finishes, wood grain patterns, stone textures, and custom colors. Architects and designers have the freedom to create stunning visual effects, harmonizing the panels with other materials for both modern and classic designs. The versatility of the finishes allows for personalized and sophisticated architectural expressions.

5. Excellent Thermal and Acoustic Insulation

The internal honeycomb structure naturally traps air within its hexagonal cells, providing outstanding thermal insulation and soundproofing. This reduces energy consumption by maintaining stable indoor temperatures and minimizing external noise intrusion. The thermal performance of aluminum honeycomb panels contributes to energy-efficient building designs, aligning with sustainable construction practices.

6. Fire Resistance and Safety

Aluminum honeycomb panels are inherently non-combustible. They do not emit toxic gases when exposed to high temperatures, enhancing the overall fire safety of buildings. This property makes them compliant with strict building codes and regulations for public and commercial spaces, ensuring peace of mind for architects, builders, and occupants alike.

7. Eco-Friendly and Sustainable

With increasing emphasis on sustainable construction, aluminum honeycomb panels stand out as an environmentally responsible choice. Aluminum is 100% recyclable, and the production processes for honeycomb panels have a lower environmental footprint compared to other cladding materials. Furthermore, the lightweight nature of the panels reduces transportation emissions and handling energy consumption.

8. Easy Installation and Maintenance

Thanks to their lightweight construction and modular design, aluminum honeycomb panels are easy to handle and install, significantly reducing construction time and labor costs. Maintenance is equally hassle-free; the panels can be cleaned effortlessly with water and mild detergents, retaining their aesthetic appeal without the need for frequent refinishing.

Disadvantages of Aluminum Honeycomb Panels

1. Higher Initial Cost

Despite their long-term benefits, aluminum honeycomb panels come with a higher upfront cost compared to conventional materials. The specialized manufacturing process and premium materials contribute to this price point. However, when considering lifecycle costs, including durability and reduced maintenance, the investment often proves to be cost-effective over time.

2. Limited Flexibility in Shape

Aluminum honeycomb panels offer excellent performance in flat applications, but their plasticity is limited. Complex curves or highly intricate shapes are challenging to achieve without advanced fabrication techniques, potentially restricting certain design ambitions.

3. Specialized Processing Requirements

Fabrication and installation of aluminum honeycomb panels require specific tools and skilled labor. Custom cuts, angles, and detailed fittings demand precision equipment, which can slightly increase project complexity. However, professional installers can overcome these challenges with the right expertise.

4. Susceptibility to Dents Under Point Impact

Although highly durable, aluminum honeycomb panels can be susceptible to dents or deformation if subjected to concentrated point impacts. Careful handling during transportation and installation is essential to preserve the pristine surface condition of the panels.

Applications of Aluminum Honeycomb Panels

Originally developed for aerospace and aviation, aluminum honeycomb panels have found widespread use across various industries due to their remarkable properties. Today, they are commonly used in:

Exterior building facades and curtain walls

Interior decorative walls and ceilings

Elevator interiors and transportation vehicles

Furniture design and custom fixtures

Commercial spaces like showrooms and malls

High-end establishments such as KTV lounges, bars, and luxury hotels

Signage and display panels

Cleanrooms and laboratory environments

Their ability to balance aesthetics with performance makes them a preferred material for both residential and commercial projects worldwide.

Conclusion

Aluminum honeycomb panels deliver a powerful combination of aesthetics, durability, and sustainability, making them an exceptional choice for modern construction and design projects. While there are some limitations, such as cost and processing complexity, the long-term benefits far outweigh these concerns. Whether enhancing the exterior beauty of a skyscraper or adding elegance to interior spaces, aluminum honeycomb panels continue to set new standards in architectural innovation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti