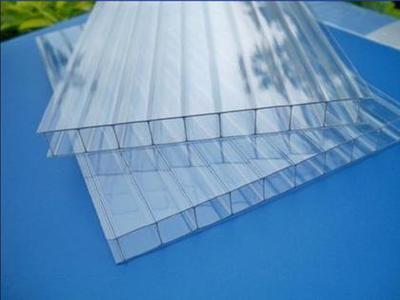

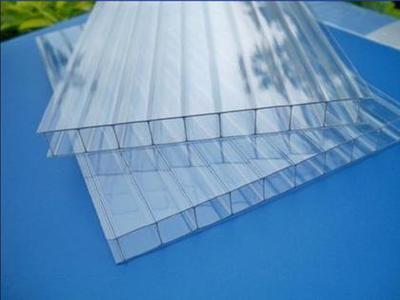

Polycarbonate sheets are versatile, durable, and structurally adaptable, making them an essential material across multiple industries. From agricultural applications to commercial architecture, the thickness and structure of polycarbonate sheets determine their best use case. These sheets, available in varying thicknesses—typically from 4mm to 20mm—are engineered to meet specific needs for insulation, transparency, impact resistance, and structural integrity.

Understanding Polycarbonate Sheet Thickness and Structure

Polycarbonate sheets are not just differentiated by thickness, but also by structural design—single-layer, double-layer, triple-layer, four-layer, honeycomb, and multi-wall designs. Each configuration affects the sheet’s thermal insulation, UV resistance, load-bearing capacity, and light diffusion.

Let’s explore how polycarbonate sheets of varying thicknesses are used across different sectors.

1. Agricultural Greenhouses: Harnessing Insulation and Light Diffusion

One of the most prominent uses of polycarbonate sheets is in agricultural greenhouses. These structures require optimal light transmission and thermal insulation to maintain healthy crop growth year-round. For these reasons, greenhouses often utilize:

6mm to 20mm polycarbonate sheets

Double-layer, triple-layer, and four-layer structures

Honeycomb and multi-wall sheets for enhanced insulation

Thicker sheets, such as 16mm to 20mm, are used in colder climates to maximize thermal efficiency, while 6mm to 8mm sheets are preferred in temperate regions where high light transmission is crucial.

Key Benefits:

2. Carport Awnings: Prioritizing Durability and Aesthetic Appeal

Carport awnings benefit from polycarbonate sheets due to their impact resistance, color variety, and cold-bending flexibility. Typically used are:

These awnings are designed not just for function, but also to complement modern architectural styles. Color-tinted sheets in bronze, gray, or blue offer aesthetic harmony while maintaining UV blocking and hail resistance.

Key Features:

Lightweight yet strong

Multiple color choices

Resistance to cracking, bending, or yellowing

Minimal maintenance required

3. Building Skylights and Lighting Panels: Emphasizing Light Transmission

Large-scale buildings—like gymnasiums, airports, and exhibition halls—incorporate polycarbonate sheets into roof lighting systems or vertical lighting strips. These installations demand maximum light transmittance with minimum structural weight.

Typical configurations include:

15mm to 20mm polycarbonate sheets

Four-layer, honeycomb, five-layer, or six-layer constructions

Locking panel systems for added wind and load resistance

Often, clear or lightly tinted polycarbonate is used to allow natural daylight while maintaining UV protection and energy efficiency.

Advantages:

Reduction in energy costs

Long-term structural integrity

High light diffusion with minimal glare

Fire retardant capabilities

4. Garage Entrances, Telephone Booths, and Urban Fixtures

In urban architecture, polycarbonate panels are often employed in transitional spaces like:

These environments benefit from:

8mm to 15mm double-layer or honeycomb sheets

High light diffusion to avoid harsh transitions

Weather resistance and vandalism protection

Design considerations often favor semi-transparent or frosted finishes that allow light while preserving privacy and enhancing visual comfort.

Benefits:

Easy installation and replacement

High impact resistance in high-traffic areas

Resistant to UV, water, and chemicals

5. Interior and Exterior Decoration: Blending Form and Function

Polycarbonate sheets also find increasing use in decorative architectural applications, both indoors and outdoors. These include:

Interior wall cladding

Partition panels

Facade highlights

Backlit signage

For decorative purposes, crystal-clear, textured, or colored polycarbonate panels are often used. Sheet thickness may vary widely depending on structural needs:

What makes polycarbonate ideal for decor is not just its visual appeal, but also its flame retardancy, lightweight structure, and ease of shaping.

Advantages:

6. Noise Barriers and Acoustic Panels: Enhancing Urban Sound Management

Beyond aesthetics and transparency, polycarbonate’s acoustic properties make it an ideal material for sound barriers along highways, railways, and industrial zones.

These structures typically utilize:

The material’s natural density and elasticity allow it to effectively absorb and deflect noise, contributing to improved urban livability.

Benefits:

7. Security Applications: Rigid, Impact-Resistant Structures

In environments requiring heightened security, such as banks, correctional facilities, and laboratories, solid polycarbonate sheets offer unmatched impact resistance—up to 250 times stronger than glass.

Common uses include:

For these applications, thickness ranges from:

Highlights:

Transparent yet shatterproof

Fire-rated and tamper-resistant

Maintains clarity over time

Conclusion: Choosing the Right Thickness for Your Polycarbonate Application

Selecting the appropriate polycarbonate sheet thickness depends entirely on the specific needs of the project—whether it's insulation, transparency, impact resistance, or decorative appeal. From greenhouses to high-security buildings, polycarbonate sheets offer a blend of functionality and flexibility that few materials can match.

As innovation continues in material science, we can expect to see polycarbonate technology evolve even further—supporting more sustainable, energy-efficient, and durable building solutions worldwide.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti