Introduction

When it comes to construction and interior design, the choice of materials is critical. Among the many materials available, magnesium oxide board (MGO) stands out as an innovative, high-performance option. While not widely known to the general public, it is essential for a wide range of construction projects. In this article, we will provide an in-depth overview of magnesium oxide boards, discussing their composition, advantages, disadvantages, and applications.

What is Magnesium Oxide Board?

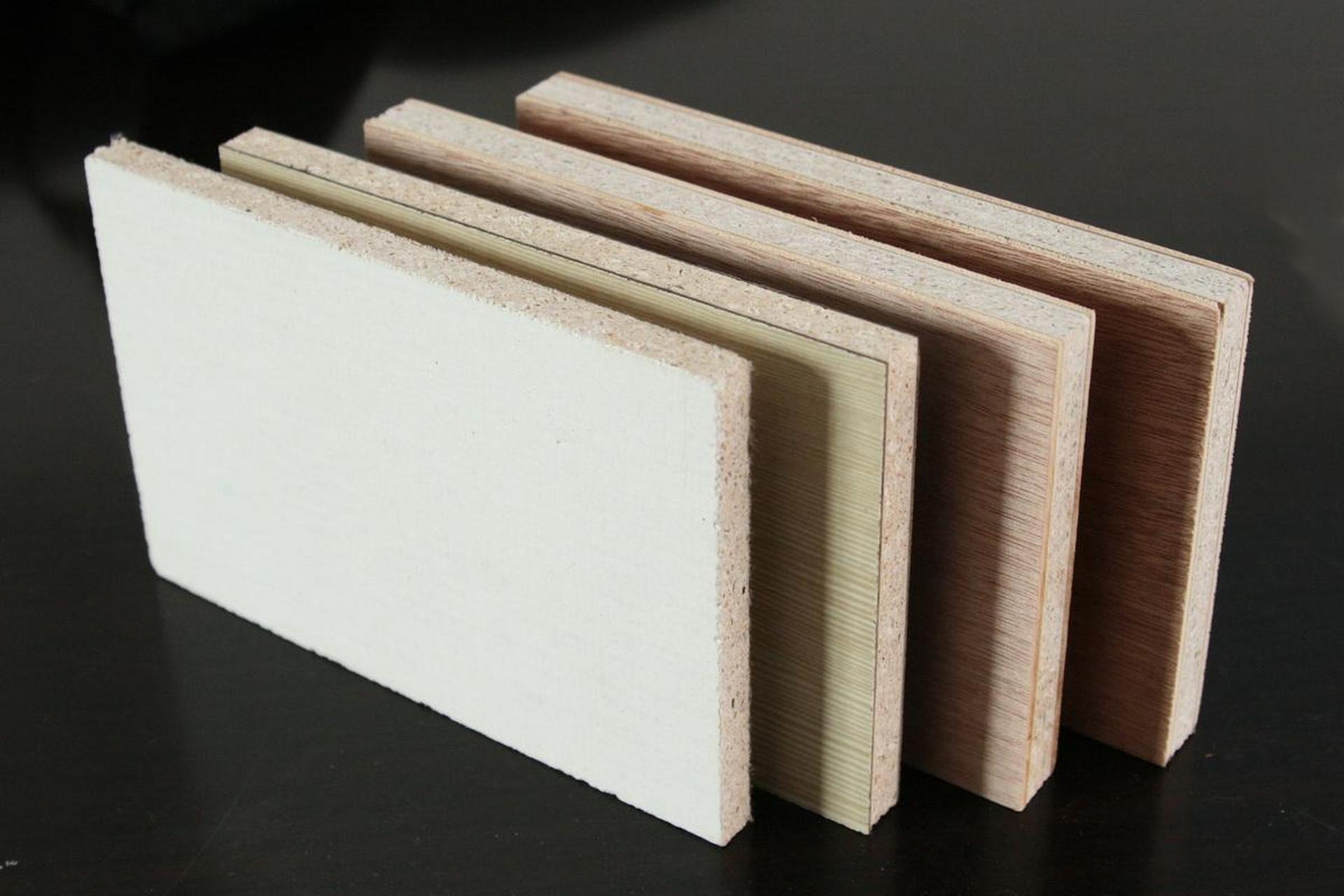

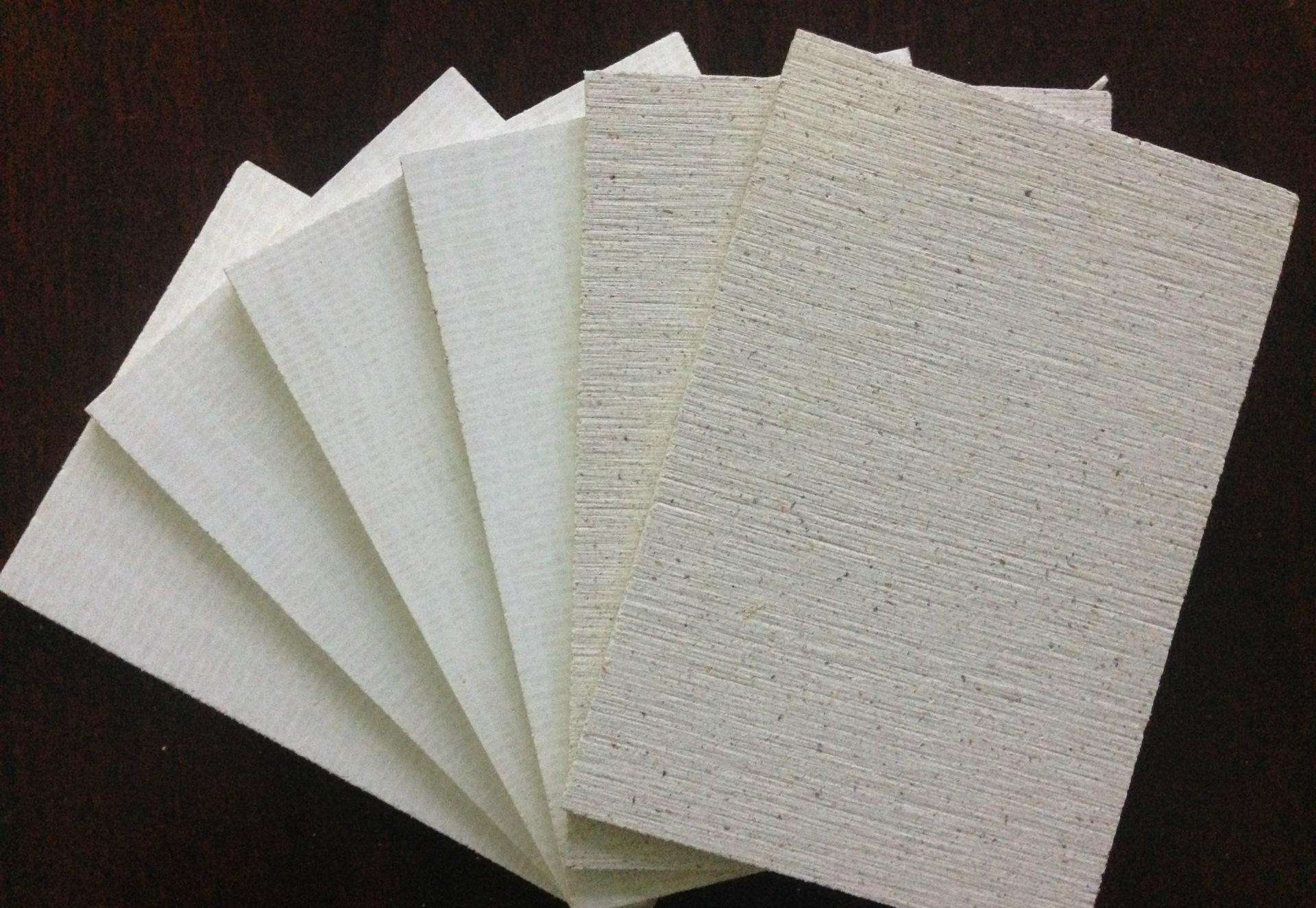

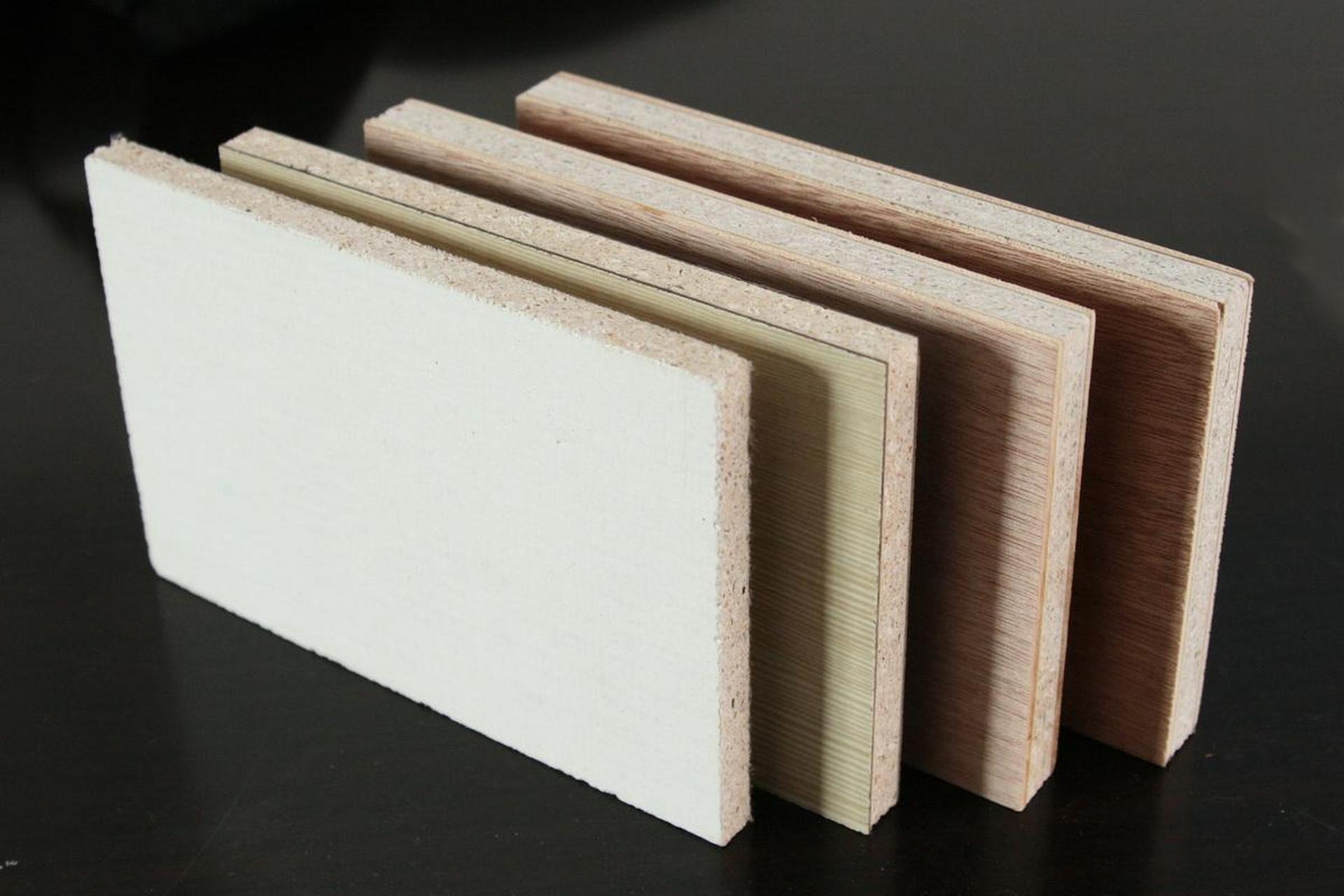

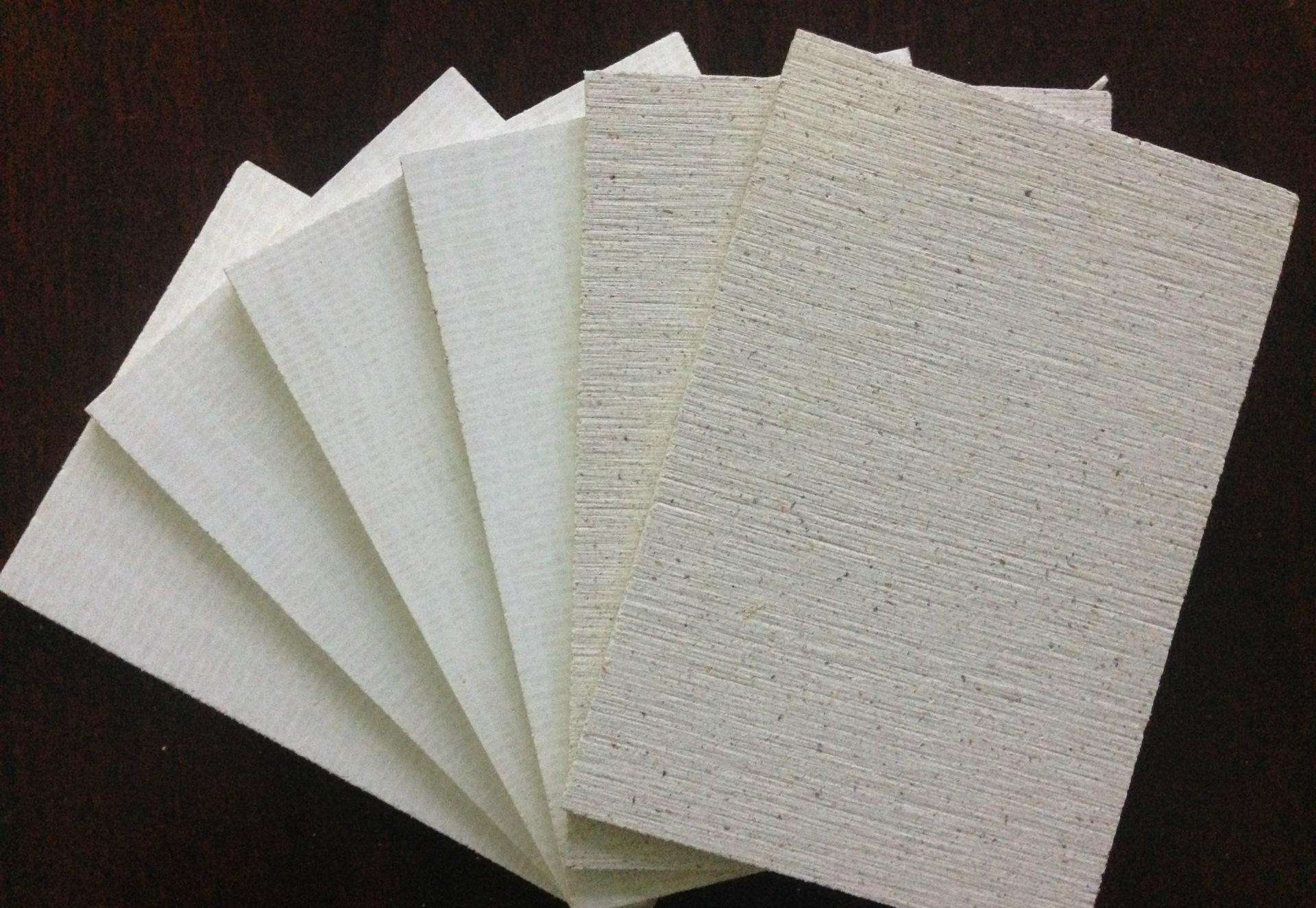

Magnesium oxide board, commonly referred to as MGO board, is a fire-resistant, water-resistant, and highly durable building material. It is made from magnesium oxide (MgO), magnesium chloride, and other fillers reinforced with medium-alkaline glass fiber mesh. The board is created using a special production process that results in a strong, lightweight, and eco-friendly product.

MGO boards are gaining widespread popularity due to their superior properties, replacing traditional materials like gypsum boards, plywood, and cement boards in various applications. Their non-toxic, mold-resistant, and fireproof nature makes them an excellent choice for both residential and commercial projects.

Advantages of Magnesium Oxide Board

1. Fireproof and Heat-Resistant

One of the standout features of MGO boards is their exceptional fire resistance. They are classified as A1 non-combustible materials, meaning they do not burn even at extreme temperatures:

Resistant to flames up to 800°C

Does not ignite or release toxic smoke at 1200°C

Fireproof partition walls built with MGO can withstand fire for over 3 hours

2. Waterproof and Moisture-Resistant

Unlike traditional materials, MGO boards maintain their structural integrity in humid environments. They do not warp, swell, or break down when exposed to water. This makes them perfect for bathrooms, kitchens, and basements, as well as regions with high humidity levels.

3. Mold, Mildew, and Termite Resistant

Thanks to their inorganic composition, MGO boards do not support the growth of mold or mildew. Additionally, they are resistant to termites and other pests, making them an ideal choice for long-term durability.

4. Lightweight and High Strength

Despite being lighter than cement boards and traditional drywall, MGO boards possess high strength and impact resistance. Their impressive bending and tensile strength allows them to be used in load-bearing applications, reducing overall structural weight.

5. Eco-Friendly and Non-Toxic

MGO boards are made from natural mineral powders and plant fibers, without harmful chemicals like asbestos, formaldehyde, or benzene. The low-energy manufacturing process further enhances their eco-friendly appeal. Additionally, their porous structure helps regulate indoor temperature and humidity levels.

6. Soundproofing Properties

MGO boards have excellent sound insulation capabilities, making them suitable for use in recording studios, hospitals, and commercial buildings where noise control is a priority.

7. Versatility and Easy Installation

MGO boards can be sawed, nailed, glued, painted, and laminated, allowing for a variety of finishing options. They can be used as:

Wall panels

Ceilings

Flooring

Fireproof doors

Furniture components

Disadvantages of Magnesium Oxide Board

1. Moisture Sensitivity if Not Properly Sealed

While MGO boards are moisture-resistant, exposure to high humidity for extended periods without proper sealing can lead to moisture absorption and eventual warping.

2. Corrosive Effects on Metal

MGO contains chloride ions, which can be corrosive to metal fasteners and reinforcements. This can be mitigated by using galvanized or stainless steel screws and fasteners.

3. Initial Cost Higher Than Traditional Drywall

Although MGO boards offer long-term benefits, their upfront cost is slightly higher compared to traditional drywall. However, their durability, fire resistance, and low maintenance make them a cost-effective choice in the long run.

4. Special Handling and Installation Required

While MGO boards are easy to install, proper sealing and moisture protection are necessary in areas with high humidity. Professional installation is recommended for best results.

Applications of Magnesium Oxide Board

1. Interior and Exterior Walls

MGO boards are widely used in wall paneling systems for residential, commercial, and industrial buildings due to their fireproof and waterproof qualities.

2. Ceilings and Partitions

Their lightweight nature and soundproofing properties make them an ideal material for ceilings and partition walls in offices, hotels, hospitals, and shopping malls.

3. Flooring Substrate

MGO boards are used as flooring underlays to provide fire resistance, sound insulation, and durability in high-traffic areas.

4. Fireproof Doors and Panels

Due to their non-combustible properties, MGO boards are commonly used in the production of fire-rated doors, elevator shafts, and fire-resistant partitions.

5. Furniture and Cabinetry

MGO boards are increasingly used in eco-friendly furniture manufacturing, replacing plywood and MDF while offering superior durability and resistance to moisture.

6. Roofing and Structural Applications

They are also used in roofing applications, either as a direct roofing material or as a base layer for tiles and shingles.

7. Insulation and Soundproofing Panels

MGO boards are often combined with insulation materials to create composite panels for enhanced thermal and acoustic insulation.

Conclusion

Magnesium oxide board (MGO) is a highly durable, fireproof, waterproof, and eco-friendly material that is revolutionizing the construction industry. With wide-ranging applications in walls, ceilings, flooring, and furniture, it is quickly becoming a preferred choice for both builders and homeowners. Although it comes with some challenges, proper installation and handling can maximize its benefits.

If you're looking for a reliable, sustainable, and high-performance building material, MGO board is an excellent investment for the future.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti