In environments where static electricity poses a risk, such as data centers, electronics manufacturing, and clean rooms, choosing the right anti-static flooring is crucial. Two popular options are anti-static raised flooring and PVC anti-static roll. Each has its own set of advantages and is suited to different applications. This article will help you understand the differences, benefits, and best use cases for both types of anti-static flooring.

Understanding Anti-Static Flooring

Definition and Importance

Anti-static flooring is designed to dissipate static electricity, preventing the buildup of electrostatic discharge (ESD) that can damage sensitive electronic equipment and create safety hazards. It is essential in environments where maintaining a controlled electrical charge is critical.

Key Considerations

When selecting anti-static flooring, consider factors such as the level of ESD protection required, ease of installation, maintenance needs, and the specific demands of your environment.

Anti-Static Raised Flooring

Composition and Properties

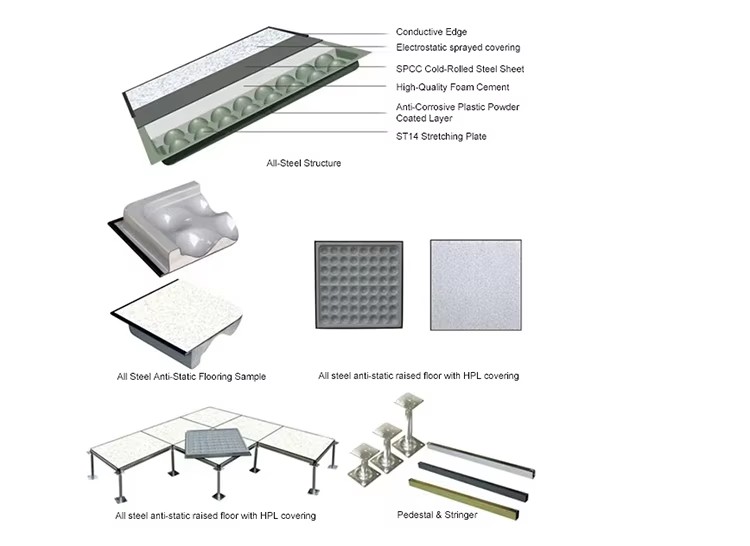

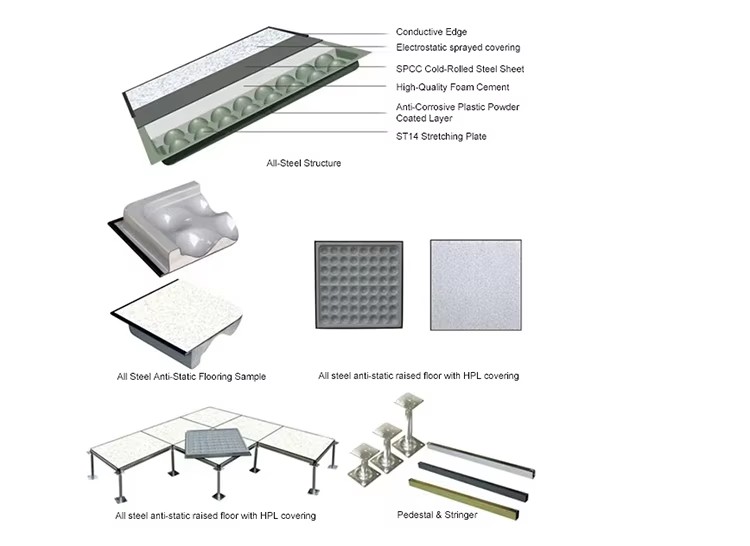

Material Composition

Anti-static raised flooring typically consists of panels made from high-density materials such as steel, aluminum, or composite materials, which are coated with an anti-static finish. These panels are supported by a grid of adjustable pedestals that create a raised floor system.

Key Properties

ESD Protection: High level of ESD protection due to the conductive materials used.

Flexibility: Allows for easy access to cables and utilities underneath the floor.

Durability: Strong and durable, capable of supporting heavy equipment.

Advantages

Enhanced Accessibility

One of the main advantages of anti-static raised flooring is the easy access it provides to the subfloor area. This is particularly beneficial in data centers and server rooms where cable management is critical.

High Load Capacity

Anti-static raised flooring is designed to support heavy equipment, making it suitable for environments with large servers, machinery, and other heavy loads.

Modularity

The modular nature of raised flooring systems allows for easy reconfiguration and expansion, providing flexibility for growing or changing needs.

Applications

Data Centers

Data centers benefit from the combination of ESD protection and easy access to underfloor cabling, making raised flooring an ideal choice.

Electronics Manufacturing

In electronics manufacturing, where precision and cleanliness are paramount, raised flooring helps maintain an organized workspace and protects sensitive equipment from static discharge.

Clean Rooms

Clean rooms require strict control over static electricity and contamination. Raised flooring meets these needs while providing a flexible and adaptable environment.

PVC Anti-Static Roll

Composition and Properties

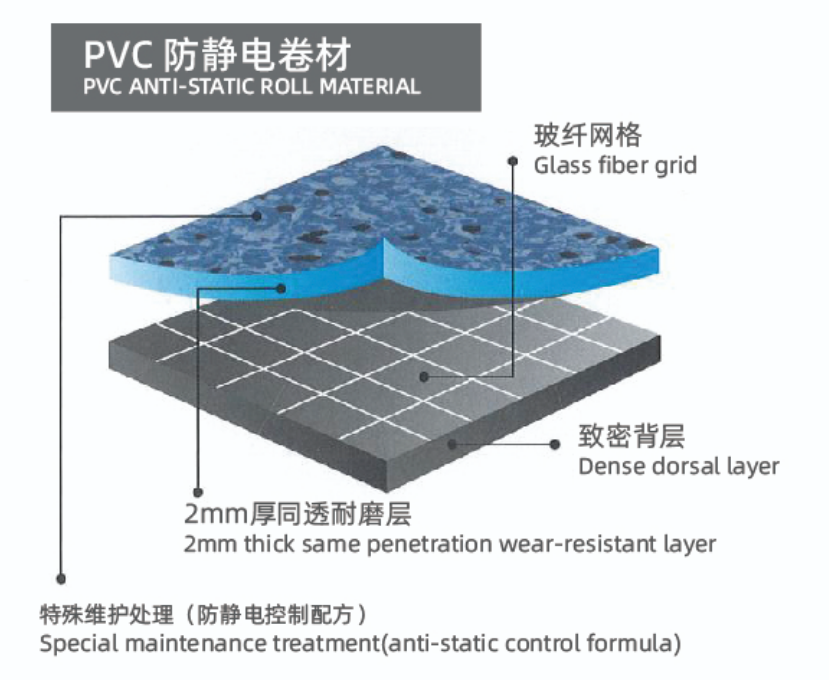

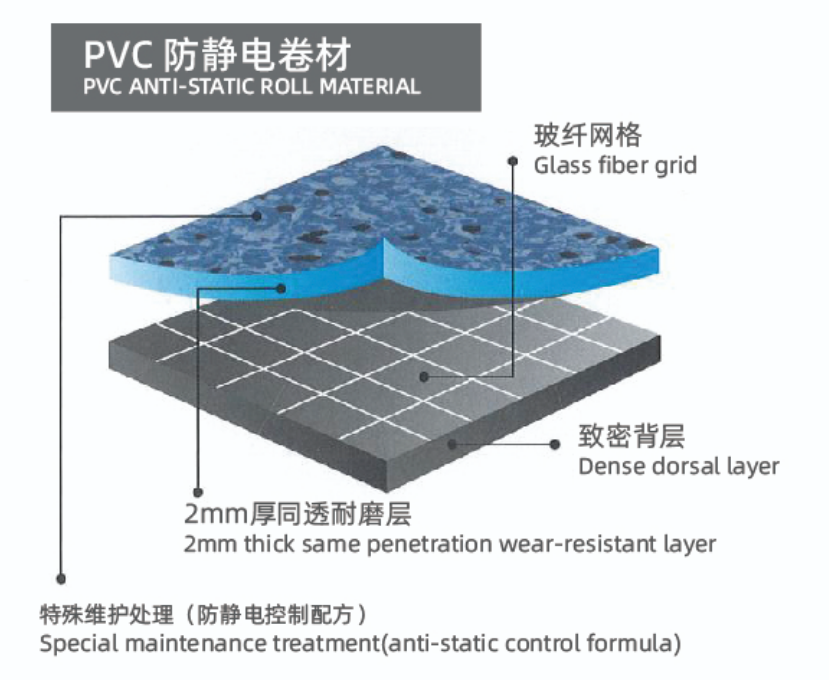

Material Composition

PVC anti-static rolls are made from polyvinyl chloride (PVC) infused with anti-static agents. These rolls come in various thicknesses and can be easily cut to fit specific areas.

Key Properties

ESD Protection: Provides reliable ESD protection through conductive or dissipative properties.

Flexibility: Can be easily cut and fitted to any space.

Ease of Installation: Simple to install, often with adhesive backing.

Advantages

Cost-Effective

PVC anti-static rolls are generally more affordable than raised flooring systems, making them an economical choice for many applications.

Ease of Installation

The rolls can be quickly installed, often with minimal disruption to existing operations. This makes them suitable for areas where downtime needs to be minimized.

Versatility

PVC anti-static rolls can be used in a variety of settings, from small labs to large manufacturing floors, due to their flexibility and ease of customization.

Applications

Laboratories

Laboratories benefit from the ESD protection and ease of cleaning provided by PVC anti-static rolls, making them a practical choice for scientific environments.

Office Spaces

In office spaces with sensitive electronic equipment, such as server rooms or IT departments, PVC anti-static rolls offer a cost-effective solution to prevent static buildup.

Retail Environments

Retail environments with electronic point-of-sale systems can use PVC anti-static rolls to protect equipment and enhance the overall safety of the space.

Comparison of Anti-Static Raised Flooring vs. PVC Anti-Static Roll

ESD Protection

Both types of flooring offer effective ESD protection, but anti-static raised flooring generally provides a higher level of protection due to its conductive materials and structure.

Installation and Maintenance

PVC anti-static rolls are easier and faster to install compared to raised flooring systems, which require more preparation and assembly. Maintenance for PVC rolls is straightforward, while raised flooring may require periodic checks to ensure stability and access to underfloor components.

Cost-Effectiveness

PVC anti-static rolls are typically more affordable upfront, whereas raised flooring systems involve a higher initial investment but may offer long-term benefits in terms of accessibility and durability.

Flexibility and Adaptability

Anti-static raised flooring offers greater flexibility and adaptability due to its modular design, making it easier to reconfigure or expand as needed. PVC anti-static rolls, while versatile, do not provide the same level of modularity.

Durability

Raised flooring systems are generally more durable and capable of supporting heavier loads compared to PVC rolls, which may wear out more quickly in high-traffic areas.

Factors to Consider When Choosing Anti-Static Flooring

Environment Type

Consider the specific requirements of your environment, such as the level of ESD protection needed, the presence of heavy equipment, and the importance of cable management.

Budget Constraints

Evaluate your budget constraints and weigh the initial costs against the long-term benefits and maintenance requirements of each flooring type.

Installation Time

Consider the installation time and potential downtime required for each option. PVC anti-static rolls can be installed quickly, while raised flooring systems may take longer to set up.

Future Needs

Think about your future needs and whether the flooring system you choose will accommodate potential changes or expansions in your workspace.

Conclusion

Choosing between anti-static raised flooring and PVC anti-static roll depends on various factors, including the level of ESD protection required, budget constraints, installation time, and the specific demands of your environment. Anti-static raised flooring offers enhanced accessibility, high load capacity, and modularity, making it ideal for data centers, electronics manufacturing, and clean rooms. On the other hand, PVC anti-static rolls are cost-effective, easy to install, and versatile, suitable for laboratories, office spaces, and retail environments. By carefully assessing your needs and priorities, you can select the most appropriate anti-static flooring solution for your workspace.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti