Introduction

In the ever-evolving world of construction, materials play a crucial role in determining the quality, durability, and efficiency of buildings. One material that has been gaining significant attention in recent years is PVC foam board. Known for its versatility and myriad benefits, PVC foam board is transforming modern construction practices. But what exactly makes this material so special? Let's dive in and explore the world of PVC foam boards and their impact on contemporary construction.

What is PVC Foam Board?

PVC foam board, or polyvinyl chloride foam board, is a type of lightweight, rigid plastic board made from PVC. It is created through a process that involves the expansion of PVC into a foam-like structure, resulting in a material that is both strong and flexible. The board's cellular structure gives it a unique combination of properties that make it ideal for various applications in construction.

Advantages of PVC Foam Board in Construction

Durability

PVC foam boards are known for their exceptional durability. They are resistant to moisture, rot, and corrosion, making them ideal for both indoor and outdoor applications. This durability ensures that structures built with PVC foam boards have a longer lifespan compared to those made with traditional materials.

Lightweight

One of the standout features of PVC foam boards is their lightweight nature. This makes them easy to transport, handle, and install, reducing labor costs and time on construction projects. Despite their light weight, they do not compromise on strength and stability.

Versatility

PVC foam boards are incredibly versatile. They can be cut, shaped, and molded into various forms, allowing for creative and customized designs. Whether used for walls, ceilings, signage, or furniture, PVC foam boards can adapt to a wide range of applications.

Cost-effectiveness

When it comes to construction, cost is always a critical factor. PVC foam boards offer a cost-effective solution without sacrificing quality. Their long lifespan and low maintenance requirements further contribute to cost savings over time.

Environmental Benefits

PVC foam boards are also environmentally friendly. They can be recycled, reducing waste and promoting sustainability in construction. Additionally, the manufacturing process of PVC foam boards is energy-efficient, further minimizing their environmental impact.

Types of PVC Foam Boards

Closed-cell PVC Foam Board

Closed-cell PVC foam boards have a denser and more uniform structure. This type of board is highly resistant to water absorption and offers excellent strength and rigidity, making it suitable for high-stress applications.

Open-cell PVC Foam Board

Open-cell PVC foam boards have a more porous structure, which makes them lighter and more flexible. While they may not be as strong as closed-cell boards, they are ideal for applications where flexibility and ease of handling are more critical.

Comparison between Types

Both closed-cell and open-cell PVC foam boards have their own advantages. The choice between them depends on the specific requirements of the project. Closed-cell boards are preferred for heavy-duty applications, while open-cell boards are chosen for their lightweight and adaptable nature.

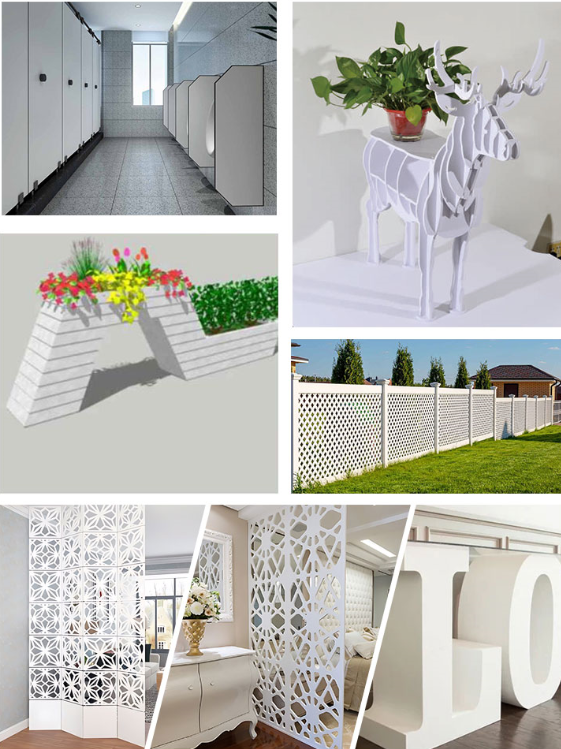

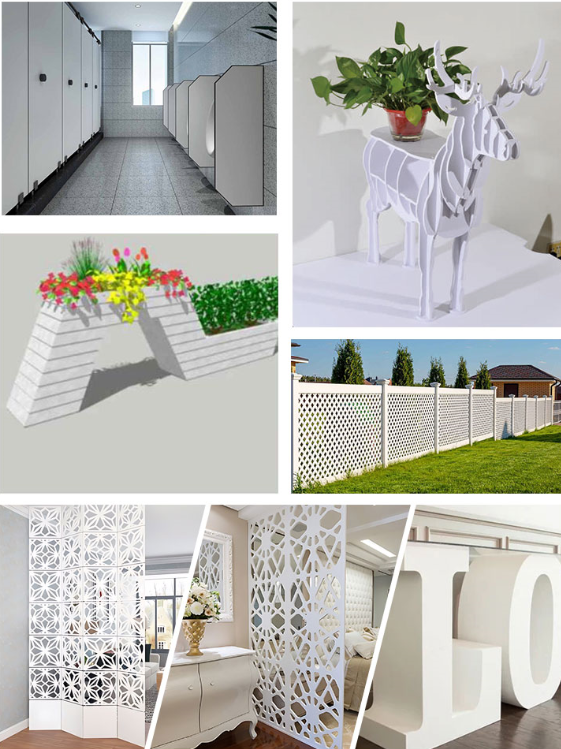

Applications of PVC Foam Board in Construction

Interior Applications

PVC foam boards are extensively used in interior construction. They are ideal for wall paneling, ceiling tiles, and decorative elements due to their lightweight and easy-to-install nature. Their smooth surface allows for various finishes, including paint and laminates.

Exterior Applications

For exterior construction, PVC foam boards are used in cladding, facades, and outdoor signage. Their resistance to weathering and UV radiation makes them a durable choice for outdoor environments.

Signage and Advertising

PVC foam boards are a popular choice in the signage and advertising industry. They can be easily cut and printed on, making them perfect for creating eye-catching signs and displays.

Furniture and Cabinetry

In the realm of furniture and cabinetry, PVC foam boards are favored for their versatility and aesthetic appeal. They can be crafted into a wide range of furniture pieces, from cabinets to shelves, offering a modern and sleek look.

PVC Foam Board vs. Traditional Materials

Comparison with Wood

Compared to wood, PVC foam boards offer better resistance to moisture and pests. They do not warp, rot, or require regular maintenance like wood. Additionally, they are lighter and easier to work with, reducing installation time and labor costs.

Comparison with Metal

PVC foam boards are non-corrosive, unlike metal, making them suitable for environments where moisture and chemicals are a concern. They also offer better thermal insulation properties, contributing to energy efficiency in buildings.

Comparison with Other Plastics

When compared to other plastics, PVC foam boards stand out for their rigidity and structural integrity. They provide a sturdier alternative to materials like polystyrene and polyethylene, which may not offer the same level of durability.

Installation and Handling of PVC Foam Boards

Cutting and Shaping

PVC foam boards can be easily cut and shaped using standard woodworking tools. This makes them convenient to work with, allowing for precise and customized installations.

Fastening and Joining

These boards can be fastened using screws, nails, or adhesives. Joining techniques such as welding and lamination are also commonly used, ensuring strong and secure connections.

Surface Finishing and Painting

The smooth surface of PVC foam boards allows for various finishing options. They can be painted, laminated, or covered with veneers to achieve the desired aesthetic effect.

Case Studies of PVC Foam Board Usage

Residential Projects

In residential construction, PVC foam boards have been used to create modern and energy-efficient homes. Their versatility allows for innovative design solutions that cater to the specific needs of homeowners.

Commercial Projects

Commercial buildings benefit from the durability and cost-effectiveness of PVC foam boards. They are used in office partitions, retail displays, and exterior cladding, providing a professional and polished look.

Industrial Projects

In industrial settings, PVC foam boards are used for protective barriers, insulation panels, and equipment enclosures. Their resistance to chemicals and moisture makes them suitable for harsh environments.

Environmental Impact of PVC Foam Boards

Recycling and Disposal

PVC foam boards are recyclable, reducing their environmental footprint. Proper disposal and recycling practices ensure that they do not contribute to landfill waste.

Sustainable Manufacturing Practices

Manufacturers of PVC foam boards are increasingly adopting sustainable practices. This includes using recycled materials and minimizing energy consumption during production, contributing to the overall sustainability of the construction industry.

Future Trends in PVC Foam Board Usage

Technological Advancements

Advancements in manufacturing technology are expected to enhance the properties and applications of PVC foam boards. This includes improvements in strength, flexibility, and environmental performance.

Market Growth Predictions

The demand for PVC foam boards is projected to grow significantly in the coming years. This growth is driven by their increasing popularity in various construction sectors and their ability to meet the evolving needs of modern architecture.

Challenges and Limitations

Potential Drawbacks

Despite their many advantages, PVC foam boards do have some limitations. They may not be suitable for high-temperature applications and can be prone to UV degradation if not properly protected. Additionally, some concerns exist regarding the release of harmful chemicals during the production and disposal processes.

Overcoming Challenges

To mitigate these challenges, it's important to use UV-resistant coatings for outdoor applications and to follow proper disposal and recycling protocols. Continuous advancements in manufacturing processes also aim to reduce the environmental impact and improve the overall performance of PVC foam boards.

Maintenance and Longevity

Tips for Maintenance

PVC foam boards require minimal maintenance. Regular cleaning with mild soap and water is usually sufficient to keep them looking new. Avoid using abrasive cleaners or harsh chemicals that could damage the surface.

Expected Lifespan

The lifespan of PVC foam boards can vary depending on the application and environmental conditions. However, with proper installation and maintenance, they can last for several decades, making them a long-term investment for construction projects.

Cost Analysis of PVC Foam Boards

Initial Cost

PVC foam boards are generally cost-effective compared to traditional materials. While the initial cost may be higher than some options, the long-term benefits and savings on maintenance and replacements justify the investment.

Long-term Savings

The durability, low maintenance requirements, and energy efficiency of PVC foam boards contribute to significant long-term savings. These factors make them a financially prudent choice for both residential and commercial construction projects.

Regulations and Standards

Compliance with Building Codes

PVC foam boards must comply with local building codes and regulations. Ensuring that the products meet these standards is crucial for safety and legal compliance in construction projects.

Safety Standards

Manufacturers of PVC foam boards adhere to strict safety standards to ensure their products are safe for use in various applications. This includes testing for fire resistance, chemical stability, and environmental impact.

Conclusion

PVC foam boards are revolutionizing modern construction with their unique combination of durability, versatility, and cost-effectiveness. They offer a sustainable alternative to traditional materials, making them an excellent choice for a wide range of applications. As technology advances and the demand for eco-friendly construction materials grows, PVC foam boards are set to play an increasingly important role in shaping the future of construction.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti