When it comes to choosing between polycarbonate sheets and acrylic sheets, the decision can be tough. Both materials are widely used in a variety of industries and applications, thanks to their clarity, lightweight properties, and versatility. However, there are important differences between them that can influence which material is better suited for specific uses.

In this article, we will dive deep into the key differences between polycarbonate and acrylic sheets, covering their physical properties, durability, applications, and more. By the end of this article, you will have a clear understanding of when to choose polycarbonate and when acrylic is the better option.

1. What is a Polycarbonate Sheet?

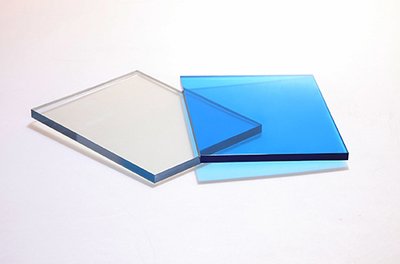

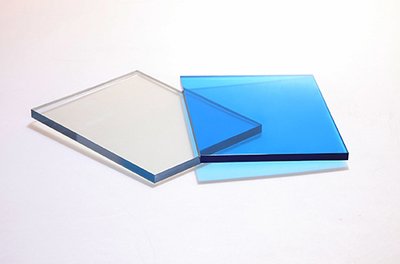

Polycarbonate sheets are a type of thermoplastic material known for their high impact resistance and toughness. Polycarbonate is a transparent material that is about 200 times stronger than glass and significantly stronger than acrylic. It is often used in applications where high impact resistance is crucial, such as safety glass, protective barriers, and greenhouse coverings.

Polycarbonate sheets can be easily molded and shaped, making them ideal for a variety of industrial applications. Additionally, polycarbonate has excellent heat resistance, making it suitable for environments that may expose it to high temperatures.

2. What is an Acrylic Sheet?

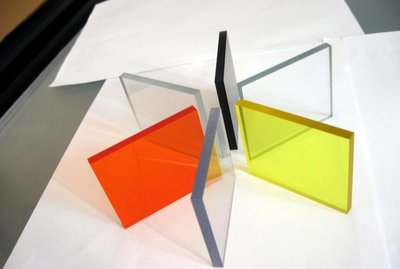

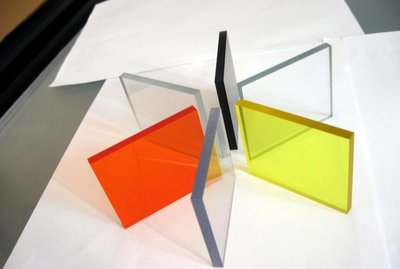

Acrylic sheets, also known as Plexiglass, are another type of transparent thermoplastic material. Acrylic is known for its optical clarity and lightweight properties. While not as strong as polycarbonate, acrylic is still much stronger than regular glass, being about 17 times more impact-resistant than glass.

Acrylic sheets are popular for applications where crystal-clear transparency is required, such as in signage, display cases, and aquariums. Acrylic can also be easily cut, polished, and shaped, making it a favorite material for decorative and aesthetic applications.

3. Impact Resistance

One of the key differences between polycarbonate and acrylic sheets is impact resistance. Polycarbonate is known for its exceptional strength and can withstand significantly more impact compared to acrylic. In fact, polycarbonate is often used as a safety material in applications such as bulletproof windows, riot shields, and protective barriers.

On the other hand, while acrylic is still stronger than glass, it is more brittle compared to polycarbonate. Acrylic can shatter or crack under heavy impact, which makes it less ideal for environments where toughness and strength are critical.

In summary:

Polycarbonate: Extremely high impact resistance, suitable for heavy-duty applications.

Acrylic: Moderate impact resistance, better for aesthetic applications.

4. Optical Clarity

Both polycarbonate and acrylic sheets are known for their transparency, but there are subtle differences in optical clarity. Acrylic sheets offer excellent optical clarity, with up to 92% light transmission, making them a great choice for applications requiring crystal-clear visuals. Acrylic also maintains its clarity over time and is resistant to yellowing.

Polycarbonate, while also clear, has slightly less light transmission at around 88-90%. Additionally, polycarbonate can become cloudy or yellowed over time due to exposure to UV radiation. However, polycarbonate sheets can be treated with UV-resistant coatings to mitigate this issue.

In summary:

Acrylic: Superior optical clarity, excellent for display cases, windows, and decorative pieces.

Polycarbonate: Good clarity but prone to yellowing without UV treatment, better suited for functional applications.

5. Durability and Strength

Polycarbonate is significantly more durable than acrylic, particularly when it comes to resistance to impact and wear. It can withstand extreme temperatures and is more resistant to chemical damage than acrylic. Polycarbonate is almost unbreakable in many everyday applications and is less likely to crack or shatter under stress.

Acrylic, while durable, is more prone to cracking or breaking under heavy pressure. It is more suited for low-impact environments where aesthetics are a higher priority than strength.

In summary:

Polycarbonate: Highly durable, almost unbreakable, suitable for demanding environments.

Acrylic: Durable but more prone to cracking; ideal for aesthetic, lower-impact applications.

6. Weight

Both polycarbonate and acrylic sheets are lightweight compared to glass, but acrylic is generally lighter than polycarbonate. This makes acrylic easier to handle and install in applications where minimizing weight is important, such as in display cases or decorative installations.

Polycarbonate, while slightly heavier, offers the advantage of greater strength and toughness. The added weight is often a trade-off for its superior durability.

In summary:

Acrylic: Lighter than polycarbonate, easier to handle.

Polycarbonate: Slightly heavier, but more robust.

7. Flexibility and Formability

When it comes to flexibility, polycarbonate is more versatile. Polycarbonate sheets can be cold-formed and shaped without breaking or cracking, which makes them ideal for applications requiring curved or complex shapes. Polycarbonate also has a higher heat resistance, so it can be used in environments where higher temperatures are a factor.

Acrylic, in contrast, is more rigid and can crack under pressure when bent or formed. It can be thermoformed, but it requires more careful handling during the process to avoid breaking.

In summary:

Polycarbonate: More flexible and formable, can be bent without breaking.

Acrylic: More rigid, better suited for flat or simple shapes.

8. Scratch Resistance

One area where acrylic outperforms polycarbonate is in scratch resistance. Acrylic sheets are naturally more resistant to scratches, which is why they are often used in applications like display cases, picture frames, and aquariums where visual clarity is crucial.

Polycarbonate, on the other hand, is more prone to scratching. However, polycarbonate sheets can be coated with a scratch-resistant layer to enhance their durability in applications where surface damage is a concern.

In summary:

Acrylic: Naturally more scratch-resistant, great for applications where clarity and aesthetics are important.

Polycarbonate: More prone to scratches, though scratch-resistant coatings are available.

9. Cost

When it comes to cost, acrylic sheets are generally more affordable than polycarbonate sheets. Acrylic is less expensive to produce, making it the preferred material for budget-conscious projects that don't require extreme durability.

Polycarbonate, being stronger and more durable, tends to be more expensive. However, the cost is often justified in applications where safety, strength, and impact resistance are top priorities.

In summary:

Acrylic: More affordable, suitable for projects with lower budgets.

Polycarbonate: More expensive but worth the investment for heavy-duty applications.

10. Applications

Both polycarbonate and acrylic sheets have a wide range of applications, but the choice between them depends on the specific needs of the project.

Common applications of polycarbonate sheets:

Bulletproof windows and safety glass.

Protective barriers and shields.

Greenhouse coverings.

Skylights and roofing materials.

Common applications of acrylic sheets:

Signage and display cases.

Aquariums and picture frames.

Decorative furniture.

Windows and skylights for residential use.

Conclusion

In conclusion, both polycarbonate and acrylic sheets offer distinct advantages depending on the specific requirements of a project. Polycarbonate sheets are the go-to option when strength, impact resistance, and durability are paramount. They excel in applications where safety and toughness are critical. On the other hand, acrylic sheets are best for projects where optical clarity, lightweight, and aesthetic appeal are more important.

By understanding the differences between these two materials, you can make an informed decision based on the performance, durability, cost, and visual requirements of your project. Whether you prioritize strength or beauty, there's a suitable option for every application.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti