Introduction

Ever heard of a building material that’s strong like cement, flexible like wood, and eco-friendly to boot? Meet cement fiberboard — the unsung hero of modern construction! Whether you're fixing up your house or managing a massive commercial project, this wonder board is probably part of it. But what exactly is it, and why is everyone talking about it?

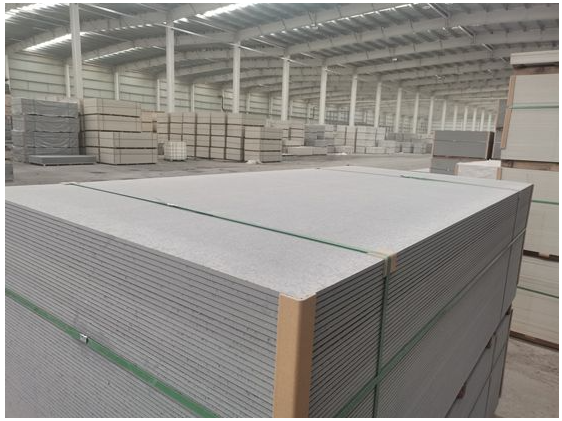

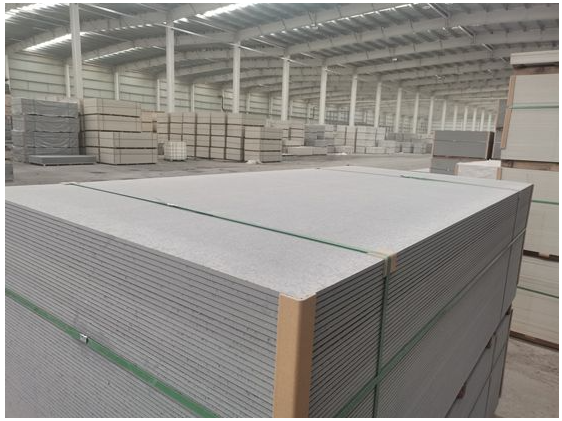

Cement fiberboard, also known as fiber cement board, is an innovative, environmentally friendly construction material that combines strength, durability, and versatility. Thanks to its unique blend of features, it's increasingly becoming the go-to solution for architects, contractors, and DIY lovers alike.

Composition and Manufacturing Process

Key Ingredients

Cement fiberboard is made from a mixture of:

Portland cement – the backbone for strength and rigidity

Silica sand – for texture and stability

Cellulose fibers – for flexibility and crack resistance

Water and other additives

This combo makes the board tough as nails but still lightweight and easy to handle.

How Cement Fiberboard is Made

The process involves:

Mixing the raw materials into a slurry.

Forming sheets through a machine process.

Pressing and curing them under high pressure and heat.

Cutting the boards into standard sizes.

Drying and quality-checking the final products.

The result? A rock-solid panel that’s ready for almost anything.

Core Characteristics of Cement Fiberboard

Moisture Resistance

No one likes soggy walls. Cement fiberboard holds its shape and integrity even in humid or wet conditions, making it perfect for bathrooms, kitchens, and exterior applications.

Fire Resistance

Here’s a bonus: this board doesn’t burn! It's non-combustible and can withstand extremely high temperatures, which makes it a lifesaver—literally—during fires.

Long Life and Durability

Once installed, this stuff sticks around for decades. It doesn’t warp, rot, or degrade easily, so it's ideal for long-term builds.

Thermal Insulation

It helps keep the heat out in summer and the warmth in during winter. That means lower energy bills and a comfier indoor climate.

Sound Insulation

Got noisy neighbors or a bustling street outside? Cement fiberboard is excellent at dampening sound.

Lightweight Nature

Despite its strength, it’s surprisingly light, which makes installation quicker and easier.

Eco-Friendliness

Made from natural materials and highly recyclable, it fits perfectly into green building projects.

Advantages of Using Cement Fiberboard

Cost-Effective Construction

Because it’s long-lasting and doesn’t need much upkeep, it saves a ton of money over time.

Time-Saving Installation

Dry installation = no waiting for things to set. Just fix it in place and move on!

No Need for Plastering

Once it's up, it’s good to go. The smooth surface doesn't require additional finishes unless you want them.

Energy Efficiency

Its insulation properties help maintain indoor temperatures, reducing heating and cooling costs.

Resistance to Mold, Pests, and Rot

Unlike wood, it doesn’t invite bugs or fungi to the party. A great option for tropical and humid climates.

Common Uses of Cement Fiberboard

Interior Wall Partitions

Lightweight and soundproof — perfect for making new rooms or dividing spaces.

Flooring Applications

Yes, it can handle foot traffic! Often used under tiles or hardwood for added support.

Exterior Walls and Cladding

Provides a sleek, modern look while protecting against weather damage.

Insulation Panels and Fireproofing

Used as fire barriers or insulation in homes and offices.

LOFT Slabs and Industrial Platforms

Sturdy enough to support heavy equipment or multi-story platforms.

Electrical Insulation Boards

Its non-conductive nature makes it ideal for use around electrical systems.

Installation and Handling

Tools and Materials Required

Step-by-Step Installation Guide

Measure and cut the boards.

Fix the frame or keel in place.

Attach the boards using screws.

Seal joints if necessary.

Paint or finish as desired.

Maintenance Tips

Available Sizes and Thickness

Standard Sizes

2440 mm x 1220 mm

2400 mm x 1200 mm

Choosing the Right Thickness

4-6 mm: For ceiling and decorative use.

8-12 mm: Perfect for walls and partitions.

16-30 mm: Best for floors or high-load areas.

Comparing Cement Fiberboard to Other Materials

Cement Board vs. Gypsum Board

Cement Board vs. Plywood

Cement Board vs. OSB

Real-World Case Studies and Applications

Residential Projects

Used for stylish, moisture-proof bathrooms, modern kitchen panels, and safe fireproof basements.

Commercial and Industrial Uses

Great for office partitions, factory floor reinforcements, and even mall exterior facades.

Environmental Impact and Sustainability

Reusability and Recycling

Even after fire or damage, many boards can be reused or recycled into new products.

Green Building Certifications

Using cement fiberboard can contribute points toward LEED and other sustainability certifications.

Conclusion

Cement fiberboard is like the Swiss Army knife of building materials — versatile, durable, eco-friendly, and easy to work with. Whether you're planning a home renovation, setting up an office, or constructing a multi-story building, it's worth considering this powerhouse board. Its features, from fire resistance to water durability and soundproofing, make it a game-changer for modern architecture.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Māori

සිංහල

Oʻzbekcha

latviešu

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Malti